Plasma Metal Pipe cutter machine, CNC metal tube cutting machine can cut mild steel with flame cutting, and cut high carbon steel, stainless steel,aluminum, copper and other non-ferrous metal with Plasma cutting; can configurate as you required, thus it is widely applied in industries such as machinery, automobile, shipbuilding, petro-chemical, war industry, metallurgy, aerospace, boiler and pressure vessel, locomotive etc.

Suitable for sheet processing, do word, etc., and other advertising equipment (vacuum molding machine, engraving machine, slotting machine, etc.,) the formation of advertising word processing line. Dozens of times higher than that of traditional craft processing efficiency.

At present, pipe intersection line cutting is widely used into many industries such as steel structure engineering, stainless steel handrails, railings, pipeline engineering, ship outfittings, highway gantry, cloth rack, stage truss, large playground, sports facilities, stainless steel furniture, bicycle frame, motorcycle frame, automobile frame, medical device, etc.

Dimension error of workpiece is too large which is cut by hand. It requires grinding after that. It usually causes low efficiency, high costs and poor welding quality. The traditional arc cutting machine is large and expensive. It needs to change molds frequently and it's limited to cut steel pipe below 60mm dia.. Also there is no beveling on the arc mouth, causing lack of beauty of welding surface appearance and also lack of firmness of welding.

CBW100 pipe intersection cutting machine/ arc cutting machine solves the problems resulted from traditional cutting. It's capable to cut flat, arc and groove, works fast (The fastest cutting speed can be only 3 seconds whether it is flat or arc). It can cut arc at any angle accurately without molds, easy operation, simple programming, durable and smooth incision.

Features

#1. High efficiency. The fastest cutting speed can be only 3 seconds whether it is flat or arc

#2. Compact with multi-functions. It's capable to cut flat, arc and groove in one machine

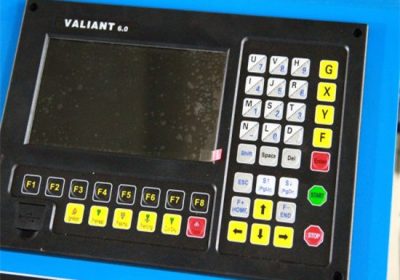

#3. Easy operation, simple programming, no complicated calculation

#4. No need mold, no special maintenance

#5. Smooth incision with beveling for welding, strong welding

#6. Durable; It lasts for 3-5years in normal use